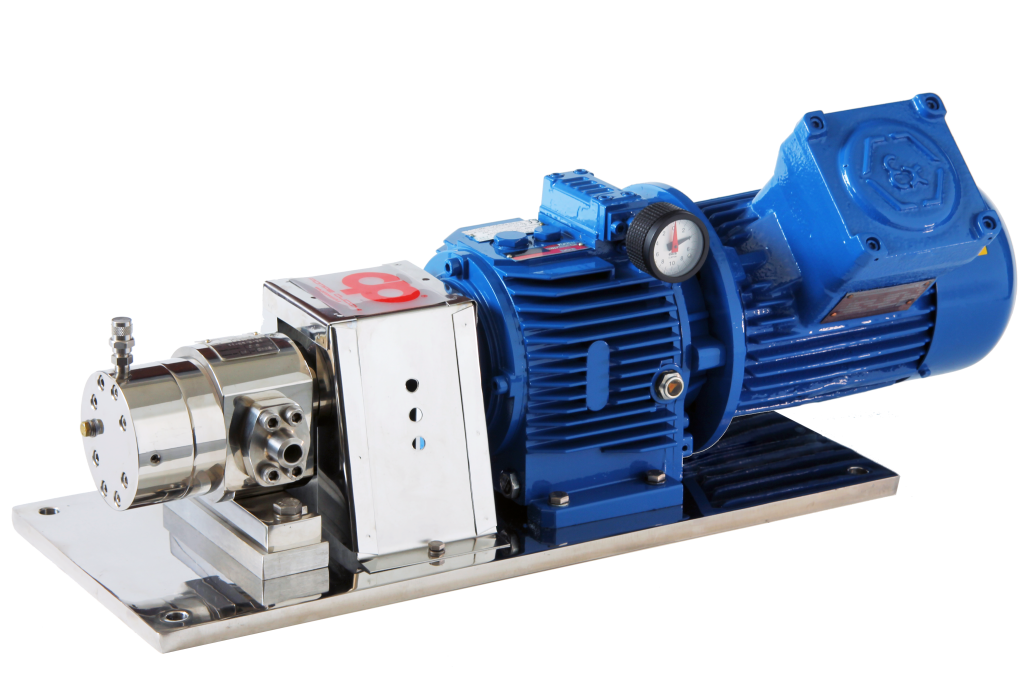

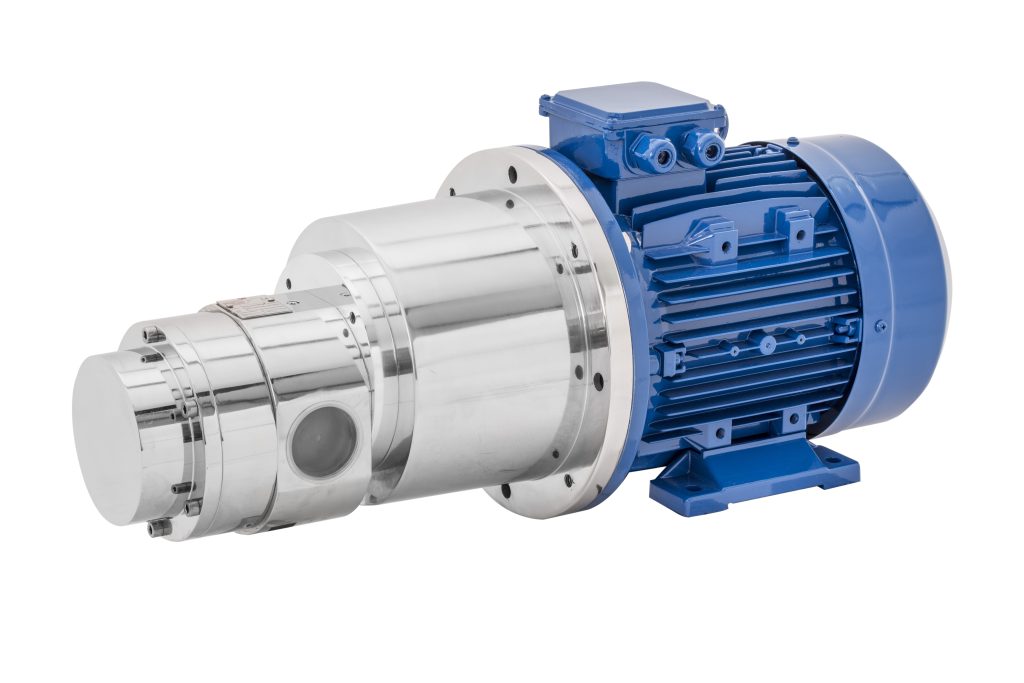

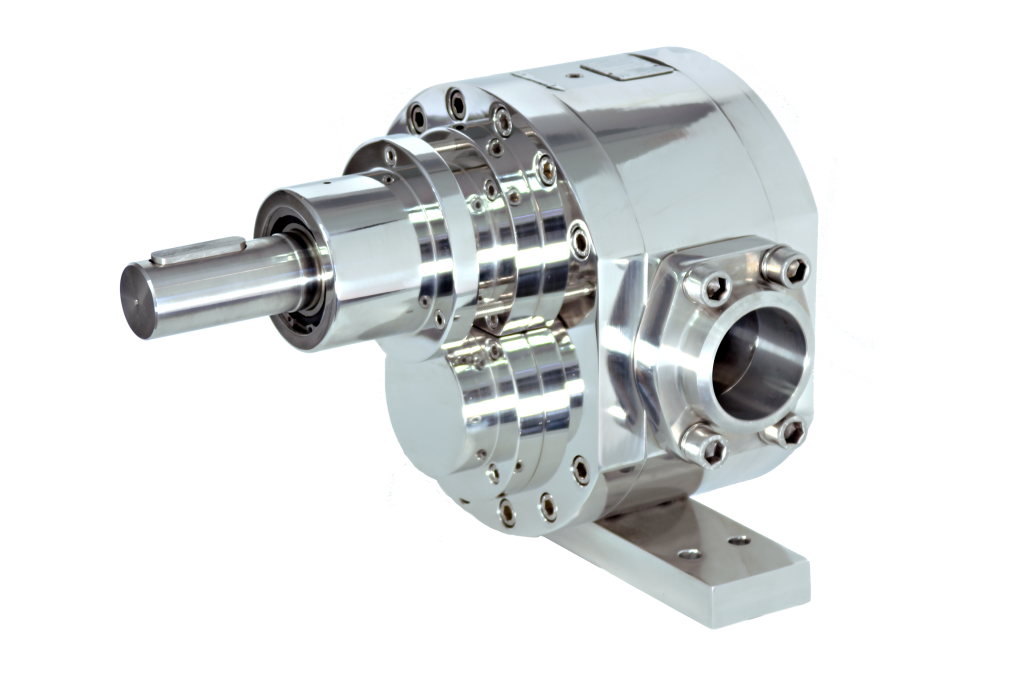

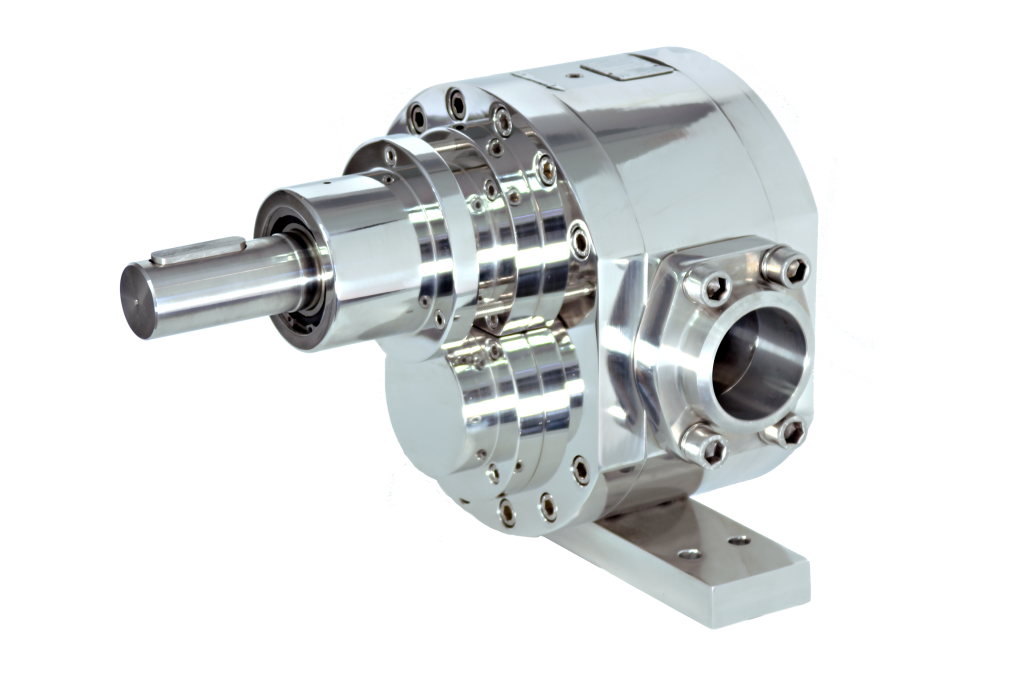

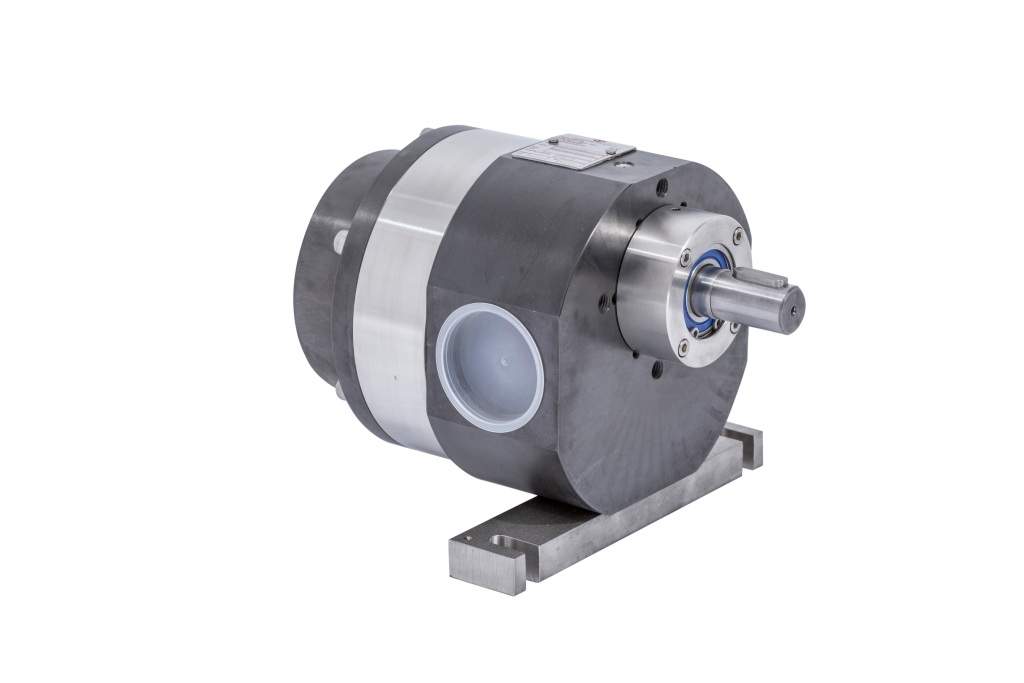

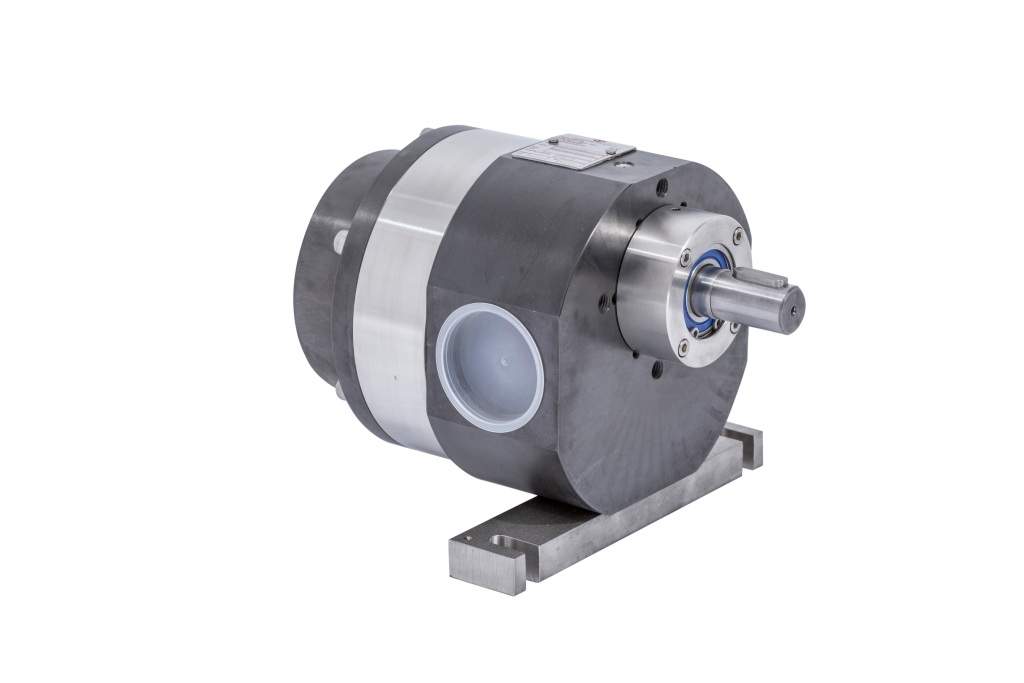

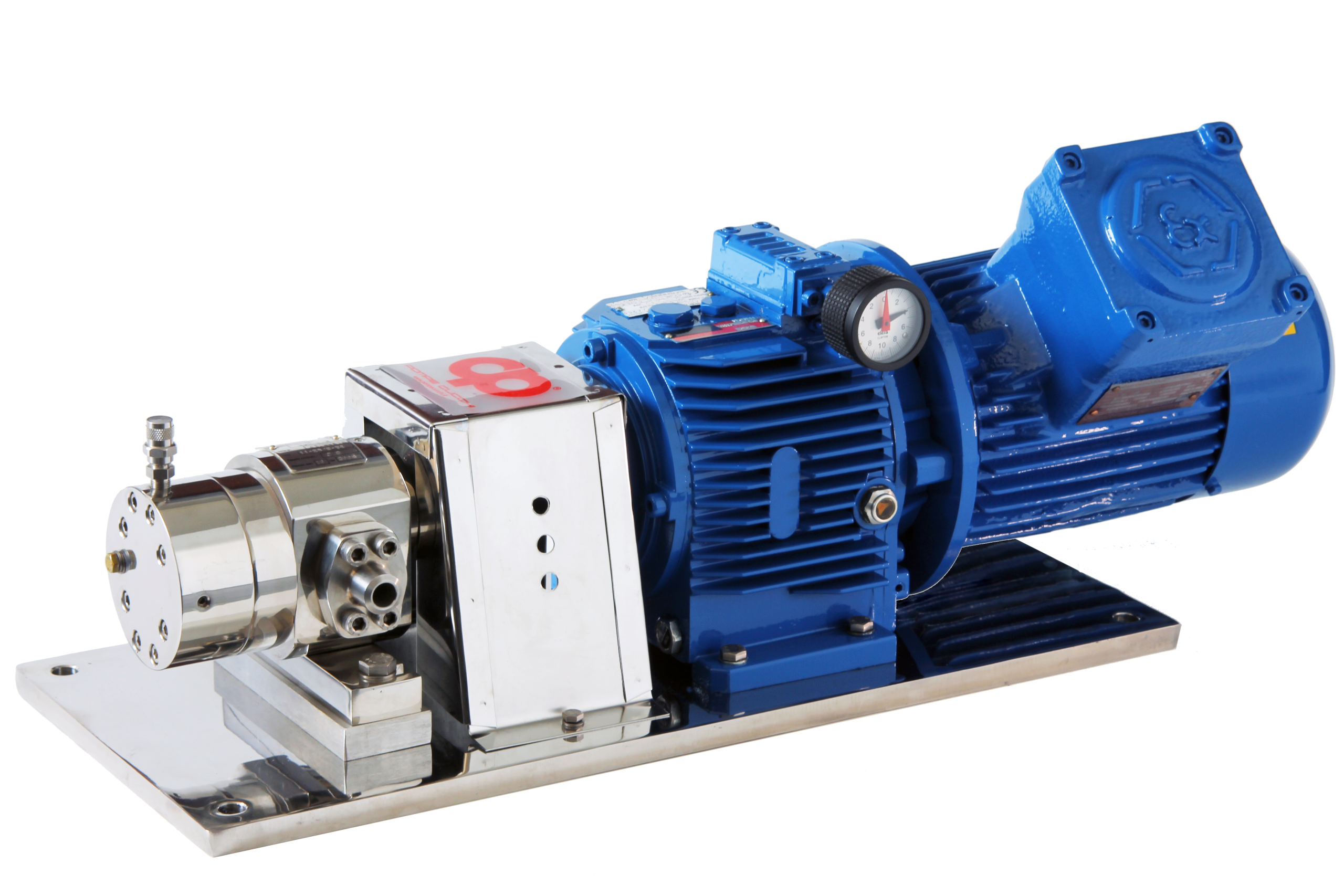

Pompe Cucchi is a designer and manufacturer of gear pumps, gear metering pumps, piston pumps and diaphragm metering pumps that has been on the market since 1948. Cucchi operates in accordance with the ISO 9001 Quality System (2015). The pumps comply with the machine list 2006/42/CE, 2004/108/CE, 2014/30/EU, 2014/35/ EU and with the standards UNI EN ISO 12100, UNI EN ISO 13732-1, UNI EN 809, UNI EN ISO 14847. At the customer’s request, the company can supply pumps in compliance with directive 2014/34/ EU (ATEX) and with API 676 and NACE MR0175 standards. All products are also EAC and TRCU 012 certified. In addition to its own production, Pompe Cucchi is the Italian distributor for Jabsco industrial line pumps, GRACO pneumatic diaphragm pumps and Grun-Pumpen drum pumps. Mission | Our mission is to design and manufacture gear pumps and metering pumps using engineering criteria that fulfill the needs of our clients: quality, reliability, ease of inspection, maintenance and cleaning and also technical support carried out by a team of competent experts who can help find solutions for multiple applications in different areas through the use of innovative materials to meet specific technical customer requirements and new processes. Production | Pompe Cucchi has installed a new 18-pallet CNC machining center capable of running 24 hours a day even without assistance (no operator) equipped with supervision software for the management, control and integration of MCM production systems. This machine has a robotic tool storage (of 400 tools). Designing | The continuous development of our project and the research for new materials have allowed us to manufacture TITANIUM and HASTELLOY C pumps. Different designs can be supplied with single mechanical seals, double tandem seals, and double back-to-back seals magnetic drive, also available in ATEX certified versions. In the case of products that are solid at room temperature (creams, waxes, fats etc.) our pumps can be equipped with a pre-heating compartment useful for hot water, steam and diathermic oil. All our pumps can be turned into metering pumps through the addition of mechanical speed variators, inverters and servomechanisms, either electric or pneumatic. We have also developed tungsten carbide bushings and wear plates as well as chromium oxide coated shafts to include them in some of our N series metering pumps, which are used for dosing mildly abrasive products. For the food industry, we also offer the option of mounting FDA-certified components for all those parts that will be in contact with liquids. Some of our series of pumps, as the result of new thermochemical treatments, include gears and shafts with surface hardness up to 4000 Vickers, allowing new applications that were thought impossible only a few years ago. All pumps are hydraulically tested. The workshop is equipped with a pump test bench with adequate software to measure, display and print various hydraulic and electrical parameters. Engineering, experience, expertise, passion and dedication, this is the formula that Pompe Cucchi employs every day to offer the best product and service. Check the catalog of our products at www.pompecucchi.it