The sleeper screws for railway application, must be realized by hot forming for the preparation of the head profile and by hot rolling process for thread.

ORT ITALIA since 1964 has a deep knowledge of the process due the long experience developed in many years: we have supplied many machineries and complete lines of production all around the world.

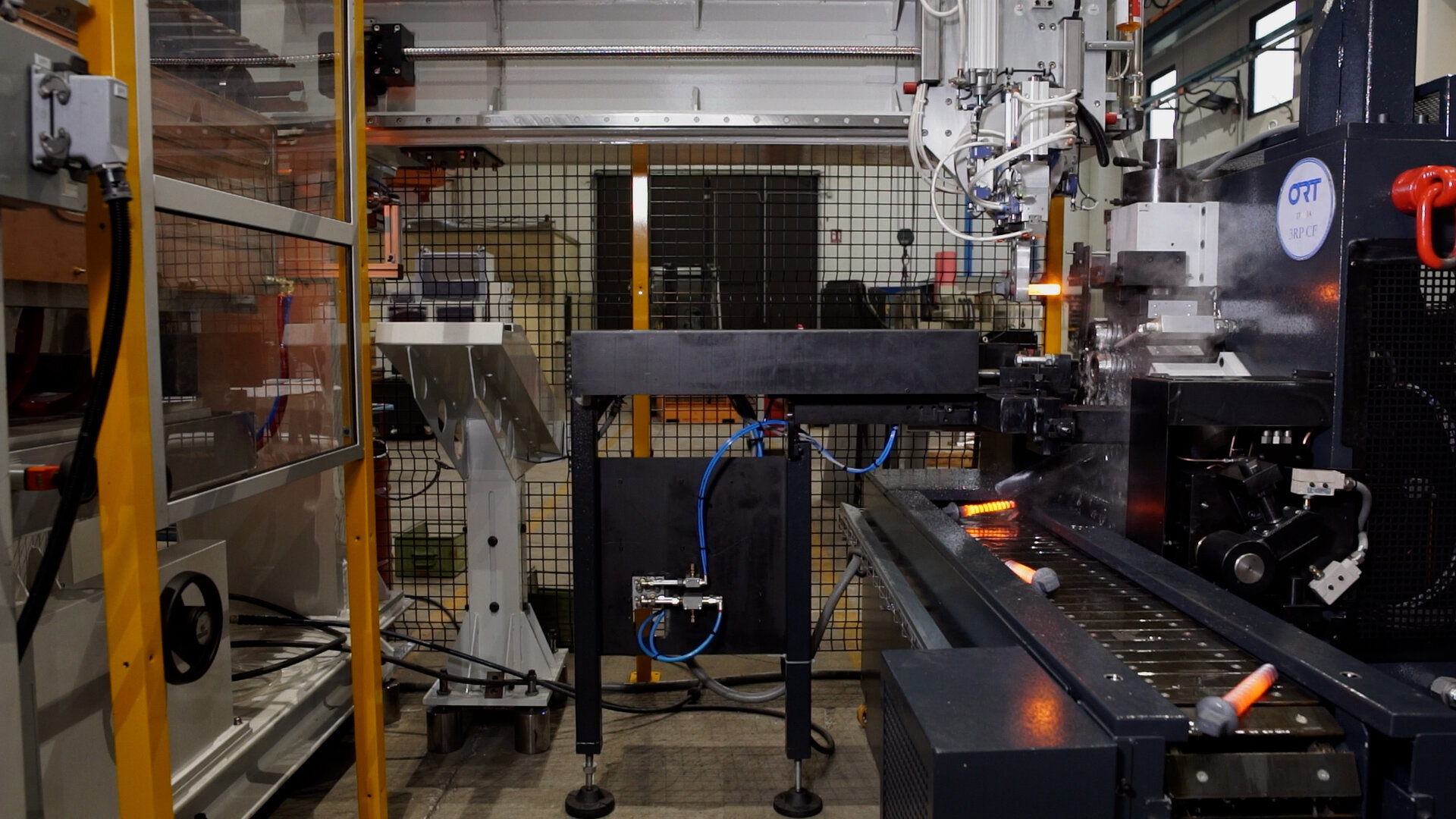

A line of production is mainly composed by an elevator of the blanks, an induction heating system with a conveyor chain, U inductor, main converter, a pick and place system to bring the pre-heated blank and to release it on an introduction device and a 3 rolling dies machine working in thru feed rolling operation.

The process must be realized at a temperature between 1.100-1.150 °C and a control of the right temperature is provided by a pyrometer: in case the level of temperature is out of the range, the line provides automatically to reject the parts before the rolling process.

The new production lines realized by ORT are also having an innovative solution to grant the cooling of all the main component of the induction heating system by the use of a Chiller instead of the more traditional water tower: this is a very important solution to avoid the water consumption and to grant a control of the temperature that will be very stable.

The renewed rolling machine is realized with a very sturdiness frame and a complete control by the PLC in order to manage all the main working parameters.